We specialize in high quality idlers, designed for specific needs. From material selection to production and testing, we follow industry standards and customer requirements. Internal components are precision engineered to ensure stable operation under extreme conditions. Adopting advanced manufacturing technology and strict quality control to ensure high precision and long life.

Adopting advanced heat treatment technology and precise control parameters to enhance the wear-resistant and anti-fatigue performance of the idlers and prolong its service life. Strict tests are conducted on the heat-treated idlers to ensure its outstanding performance.

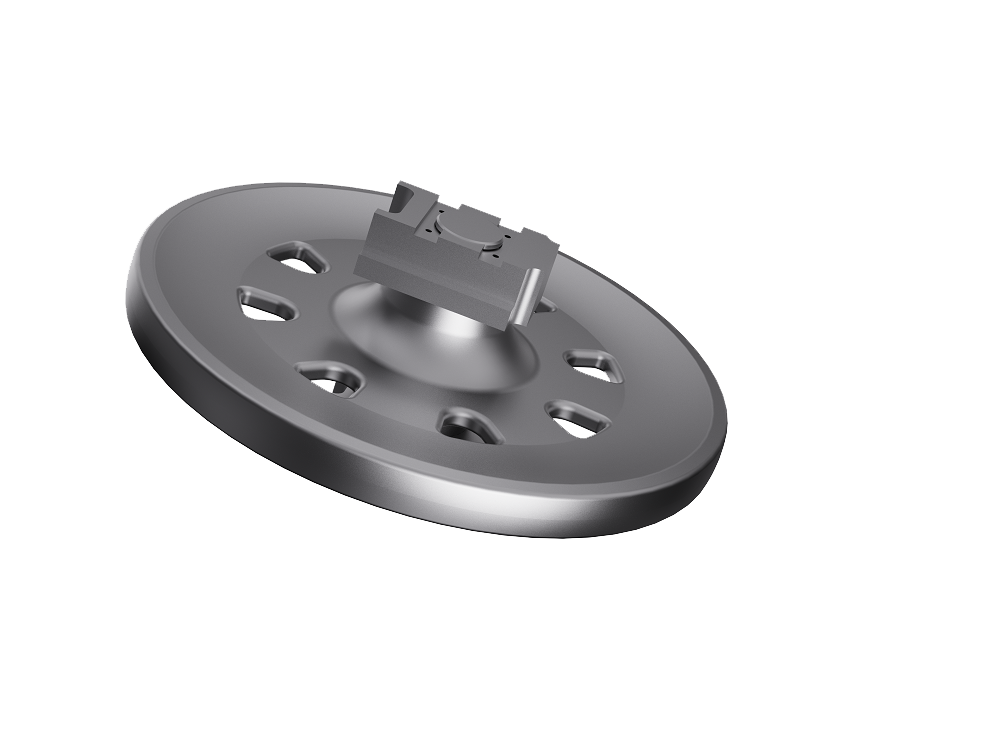

ROMETTLE idlers use precision technology and high-precision sand molds for accurate molding. Made of high-strength cast iron, alloy cast iron, or special steel, the casting process is optimized by simulation software. Customizable, adaptable, and with short production cycles, they undergo heat treatment for fatigue resistance. Widely used in machinery and mining, they are efficient, adaptable, and economical.