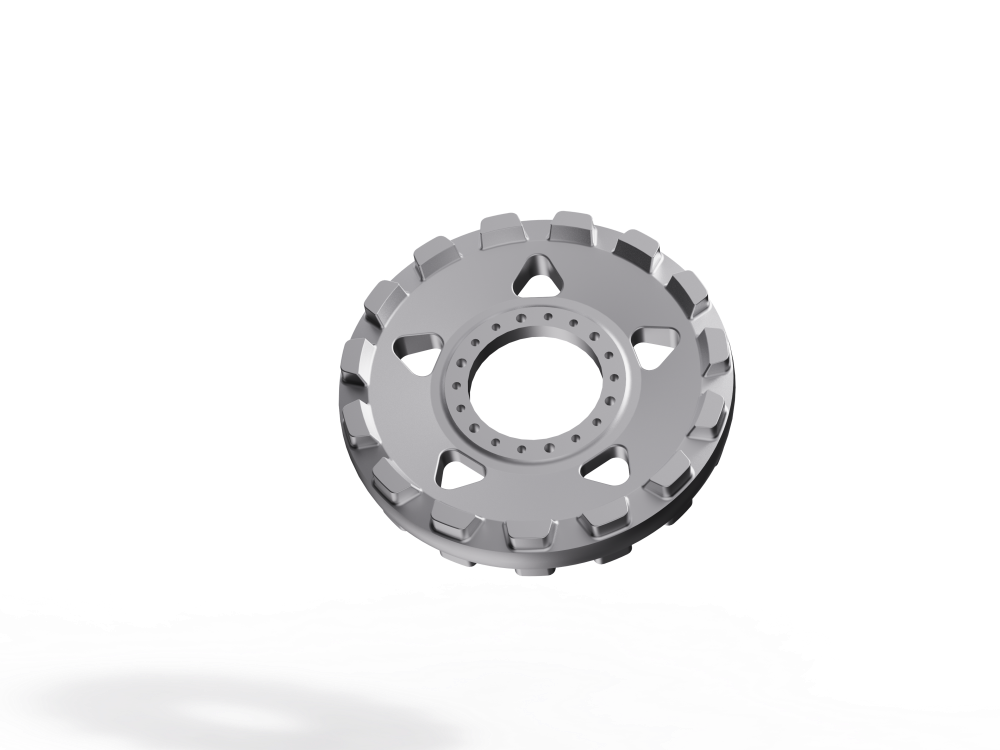

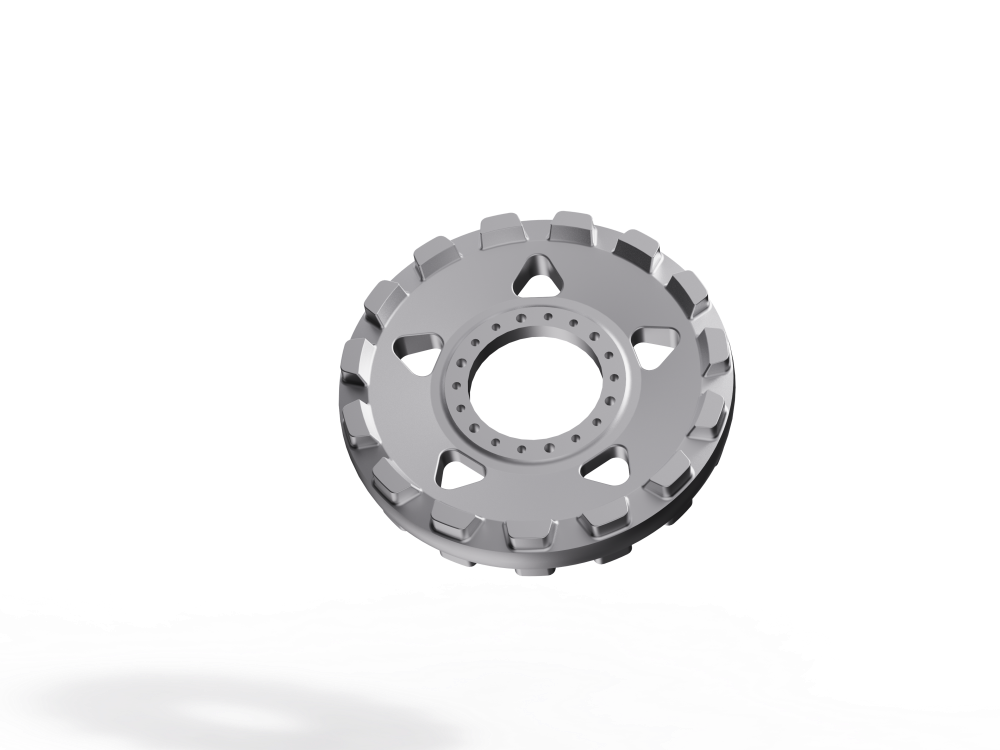

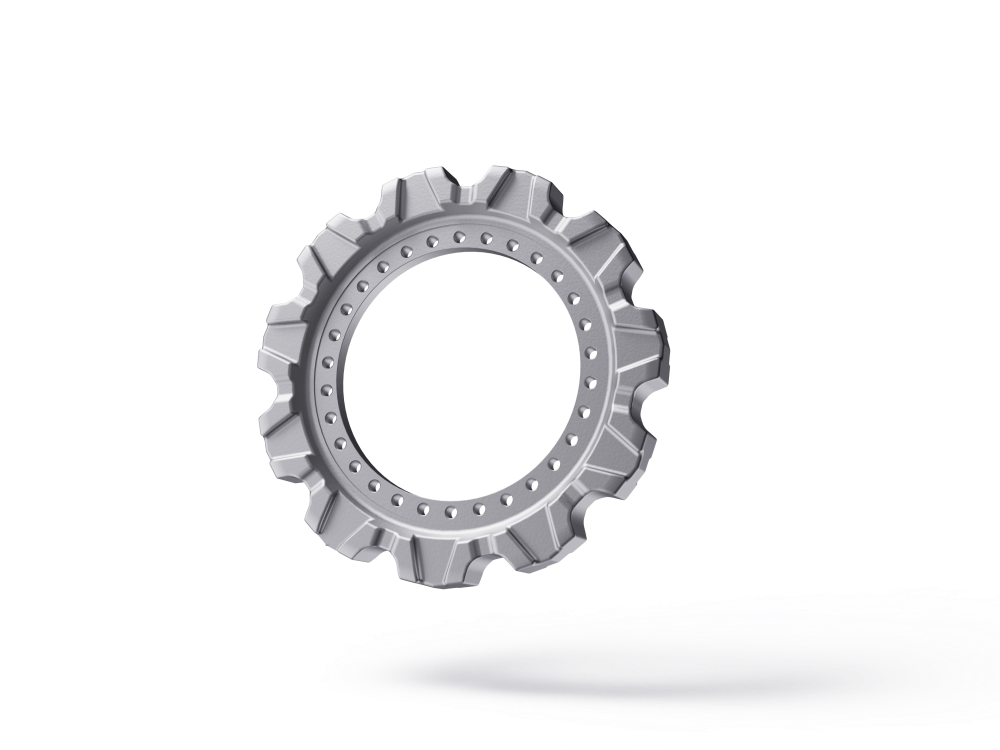

ROMETTLE's sprocket are made of top-quality materials, developed for harsh environments and are suitable for high wear and shock loads. Precision design and machining ensure standardized components. Customized heat treatments increase surface and core hardness, enhancing resistance to bending and wear.

ROMETTLE sprockets are built by precision craftsmanship and cast in high-precision sand molds to ensure precise molding and stable quality. Strength and wear resistance are enhanced by heat treatment, and precision machining ensures accuracy and finish. High-quality painting provides protection against corrosion. Its excellent strength, abrasion resistance and corrosion resistance are able to cope with harsh working conditions, showing long life and high performance.